Our latest commercial project took us to a large loading bay in New Westminster. This high-traffic loading bay was made of concrete floors and experiencing wash out and void under the slabs. Leaving little support for the heavy vehicles and machinery in the space, our client needed an effective solution that would allow traffic to continue flowing in and out of the garage. Our client needed a solution that was non-invasive, quick, and addressed their concerns.

The Issue:

The Solution:

Calling in the True Level Concrete team for commercial concrete repair.

There are many vehicles flowing through the loading bays throughout the day, so maintaining a safe avenue for traffic is paramount.

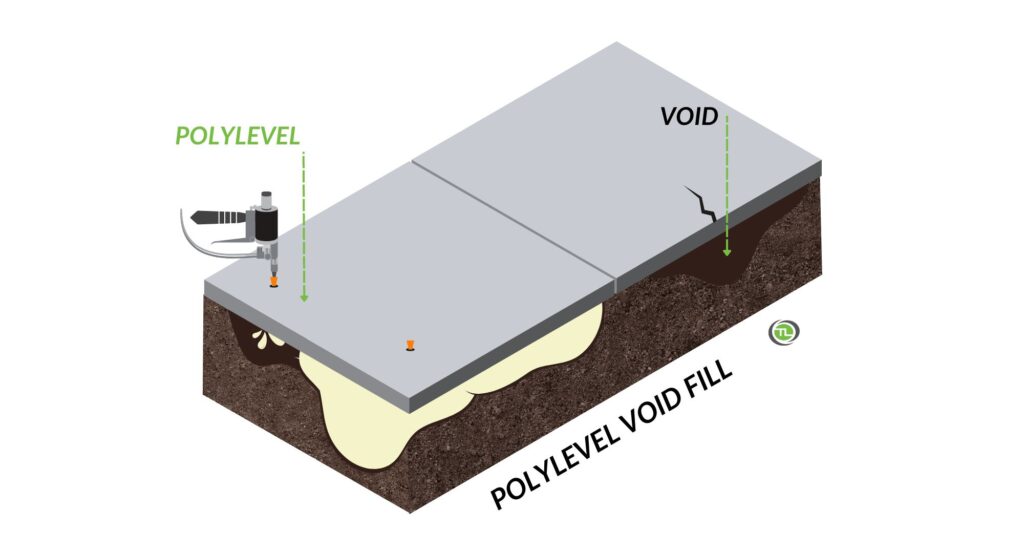

We used PolyLevel foam to fill, support, and stabilize the concrete.

PolyLevel is a lightweight liquid solution that gets injected under the slabs as a liquid, and then expands into a high-density foam. It is a hydrophobic foam that will not wash out or allow water to invade and its high density allows for it to lift, support, and stabilize extremely heavy loads. It’s an environmentally friendly material that will not degrade over time.

As a bonus, this method of repair allowed for traffic to continue going in and out of the loading bay area even during the height of our project.

This was the perfect solution for this project.

It might not look different from here, but the entire floor is now filled and supported with PolyLevel foam.

Issues Addressed:

PolyLevel concrete repair is a highly effective and non-invasive process. It is a perfect solution to avoid the hassle of removing and replacing concrete and can be completed in a short amount of time for convenience.

If you are seeking concrete repair or foundation repair, reach out to our friendly team. Our specialists can assess your concerns and provide you with a free, detailed, no-obligation estimate on the spot.

Date: March 2024.

Time: 5 days to complete project.

Certified PolyLevel Installer: True Level Concrete.

Products Installed: 16,585 Lbs. PolyLevel Material.